Izvi zvinotevera maitiro akazara ekugadzira kubva kuSMT (pamusoro-soro tekinoroji) kuenda kuDIP (dual in-line package), kune AI yekuona uye ASSY (assembly), nevashandi vehunyanzvi vanopa nhungamiro mukati mekuita. Iyi nzira inovhara iyo yakakosha zvinongedzo mukugadzirwa kwemagetsi kuve nechokwadi chepamusoro-mhando uye kugadzirwa kwakanaka.

Pedzisa kugadzira maitiro kubva kuSMT → DIP→ AI yekuongorora→ ASSY

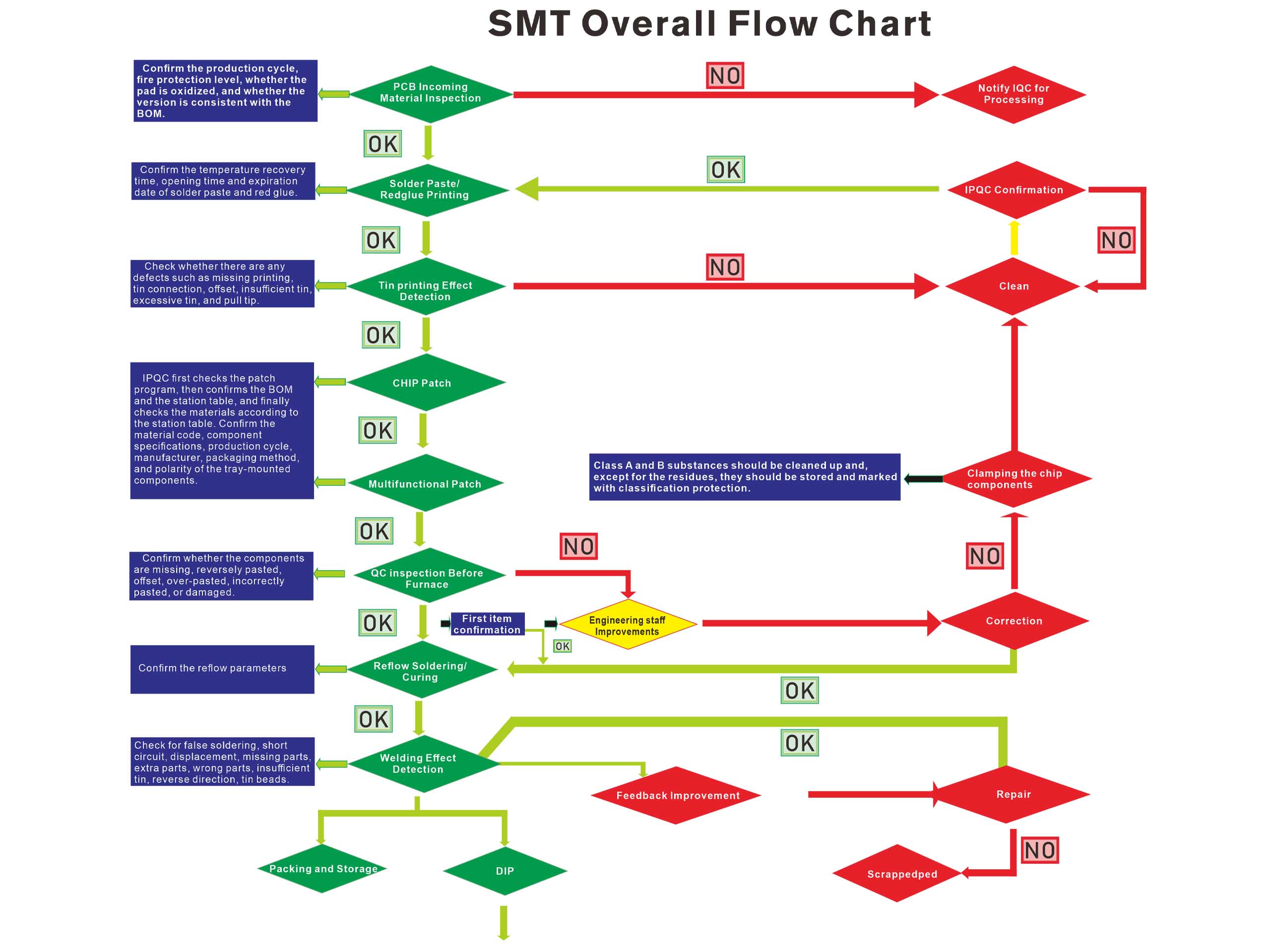

1. SMT (pamusoro-soro tekinoroji)

SMT ndiyo musimboti muitiro wekugadzira zvemagetsi, unonyanya kushandiswa kuisa pamusoro pegomo components (SMD) paPCB.

(1) Solder paste kudhinda

Zvishandiso: solder paste printer.

Matanho:

Gadzirisa PCB pane printer workbench.

Dhinda solder paste nemazvo pamapadhi ePCB kuburikidza nesimbi mesh.

Tarisa kunaka kwe solder paste printing kuti uone kuti hapana offset, kushaikwa kudhindwa kana overprinting.

Pfungwa huru:

Iyo viscosity uye ukobvu hweiyo solder paste inofanira kusangana nezvinodiwa.

Mesh yesimbi inoda kucheneswa nguva nenguva kuti isavharika.

(2) Kuiswa kwechikamu

Zvishandiso: Sarudza uye Isa Muchina.

Matanho:

Rodha zvinhu zveSMD mune inodyisa yemuchina weSMD.

Muchina weSMD unotora zvinhu kuburikidza nenozzle uye nekunyatsozviisa panzvimbo yakatarwa yePCB zvinoenderana nechirongwa.

Tarisa kurongeka kwekuisa kuti uone kuti hapana offset, zvisizvo zvikamu kana zvisipo.

Pfungwa huru:

Iyo polarity uye kutungamira kwezvikamu kunofanirwa kuve kwakarurama.

Iyo nozzle yemuchina weSMD inoda kuchengetedzwa nguva nenguva kudzivirira kukuvadzwa kwezvinhu.

(3) Reflow soldering

Equipment: Reflow soldering vira.

Matanho:

Tumira iyo yakasimudzwa PCB mu reflow soldering vira.

Mushure mematanho mana ekutanga kupisa, tembiricha isingaperi, kuyerera uye kutonhora, iyo solder paste inonyungudutswa uye yakavimbika solder joint inoumbwa.

Tarisa mhando ye soldering kuti uone kuti hapana chakakanganisika senge inotonhora solder majoini, bridging kana tombstones.

Pfungwa huru:

Iyo tembiricha curve ye reflow soldering inoda kugadziridzwa zvinoenderana nehunhu hweiyo solder paste uye zvikamu.

Calibrate tembiricha yechoto nguva nenguva kuti ive nechokwadi chekugadzika welding mhando.

(4) AOI kuongorora (otomatiki optical inspection)

Zvishandiso: otomatiki optical yekuongorora chiridzwa (AOI).

Matanho:

Optically tarisa iyo yakatengeswa PCB kuti uone kunaka kwemajoini ekutengesa uye chikamu chekukwira chaiko.

Rekodha uye ongorora kukanganisa uye mhinduro kune yapfuura maitiro ekugadzirisa.

Pfungwa huru:

Chirongwa cheAOI chinoda kuvandudzwa maererano nemagadzirirwo ePCB.

Gadzirisa midziyo nguva nenguva kuti uone kuti yakanyatsoonekwa.

2. DIP (dual in-line package) maitiro

Nzira yeDIP inonyanya kushandiswa kuisa kuburikidza ne-hole components (THT) uye inowanzo shandiswa pamwe chete neSMT maitiro.

(1) Kupinza

Zvishandiso: manual kana otomatiki yekuisa muchina.

Matanho:

Isa iyo kuburikidza-gomba chikamu munzvimbo yakatarwa yePCB.

Tarisa chokwadi uye kugadzikana kwekuiswa kwechikamu.

Pfungwa huru:

Mapini echikamu anoda kuchekwa kusvika pakureba kwakakodzera.

Ita shuwa kuti chikamu polarity chakarurama.

(2) Wave soldering

Equipment: wave soldering vira.

Matanho:

Isa iyo plug-in PCB mune wave solder vira.

Solder mapini echikamu kuPCB pads kuburikidza neave soldering.

Tarisa kunaka kwekutengesa kuti uone kuti hapana majoini anotonhora ekutengesa, mabhiriji kana majoini ari kubuda.

Pfungwa huru:

Iyo tembiricha uye kumhanya kwema wave soldering inoda kugadziridzwa zvinoenderana nehunhu hwePCB uye zvikamu.

Chenesa bhati ye solder nguva dzose kudzivirira tsvina kubva pakukanganisa kunaka kwekutengesa.

(3) Manual soldering

Gadzirisa nemaoko PCB mushure mekunyungudika kwemafungu kuti ugadzirise kukanganisa (senge inotonhora solder majoini uye bhiriji).

Shandisa simbi yakanyungudutswa kana pfuti yemhepo inopisa kune solder yemunharaunda.

3. Kuonekwa kweAI (artificial intelligence yekuona)

Kuonekwa kweAI kunoshandiswa kuvandudza kushanda uye kurongeka kwekuonekwa kwemhando.

(1) AI kuona kuona

Zvishandiso: AI inoona yekuona system.

Matanho:

Bata mifananidzo yepamusoro-tsanangudzo yePCB.

Ongorora mufananidzo kuburikidza neAI algorithms kuti uone kukanganiswa kwekutengesa, component offset uye mamwe matambudziko.

Gadzira mushumo wekuyedza uye woidzosera kumaitiro ekugadzira.

Pfungwa huru:

Iyo AI modhi inoda kudzidziswa uye kugadziridzwa zvichibva pane chaiyo yekugadzira data.

Gadziridza iyo AI algorithm nguva nenguva kuti uvandudze iyo yekuona chokwadi.

(2) Kuedza kushanda

Zvishandiso: Automated test equipment (ATE).

Matanho:

Ita bvunzo dzekuita kwemagetsi paPCB kuti uone mabasa akajairwa.

Rekodha bvunzo mhinduro uye ongorora zvikonzero zvezvakaremara zvigadzirwa.

Pfungwa huru:

Maitiro ekuyedza anofanirwa kugadzirwa zvinoenderana nehunhu hwechigadzirwa.

Gara uchigadzirisa midziyo yekuyedza kuti uone chokwadi chebvunzo.

4. ASSY maitiro

ASSY inzira yekuunganidza PCB uye zvimwe zvikamu kuita chigadzirwa chakazara.

(1) Mechanical assembly

Matanho:

Isa iyo PCB mudzimba kana bracket.

Batanidza zvimwe zvinhu zvakaita setambo, mabhatani, uye masikirini ekuratidzira.

Pfungwa huru:

Ita shuwa gungano rakarurama kudzivirira kukanganisa kuPCB kana zvimwe zvikamu.

Shandisa anti-static maturusi kudzivirira static kukuvara.

(2) Software kupisa

Matanho:

Pisa iyo firmware kana software mundangariro yePCB.

Tarisa mhedzisiro inopisa kuti uve nechokwadi chekuti software inomhanya zvakajairika.

Pfungwa huru:

Chirongwa chekupisa chinofanira kuenderana neshanduro yehardware.

Ita shuwa kuti nzvimbo yekutsva yakagadzikana kudzivirira kukanganisa.

(3) Kuedza kwemuchina wose

Matanho:

Ita bvunzo dzinoshanda pane zvakaunganidzwa zvigadzirwa.

Tarisa chitarisiko, kuita uye kuvimbika.

Pfungwa huru:

Zvinhu zvekuyedza zvinofanirwa kuvhara mabasa ese.

Rekodha bvunzo data uye gadzira mishumo yemhando.

(4) Kurongedza uye kutumira

Matanho:

Anti-static packaging yezvigadzirwa zvinokwanisa.

Label, rongedza uye gadzirira kutumirwa.

Pfungwa huru:

Packaging inofanira kusangana nekutakura uye kuchengetedza zvinodiwa.

Rekodha ruzivo rwekutumira kuti utarise nyore.

5. Pfungwa huru

Kudzora kwezvakatipoteredza:

Dzivirira static magetsi uye shandisa anti-static midziyo uye maturusi.

Kugadziriswa kwemidziyo:

Gara uchichengetedza uye kuenzanisa midziyo yakadai semaprinta, michina yekuisa, maovheni ekudzoreredza, mavheji ekutesa mavheni, nezvimwe.

Process optimization:

Optimize process parameters zvinoenderana nemamiriro chaiwo ekugadzira.

Quality control:

Maitiro ega ega anofanirwa kuongororwa zvemhando yepamusoro kuti ive nechokwadi chegoho.